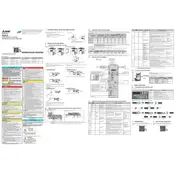

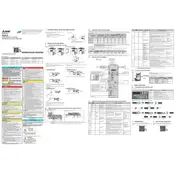

Mitsubishi E860-E FR-E860-0017-0.75K-E Safety Guideline

To configure the basic parameters, access the inverter's digital operator panel. Navigate through the parameter settings using the menu buttons, and adjust settings such as frequency, voltage, and motor control mode according to your application's requirements.

First, check the motor connections and ensure there are no short circuits or grounding issues. Then, verify that the load is within acceptable limits. Consider adjusting the acceleration and deceleration times if the error persists. Consult the manual for specific error codes related to overcurrent conditions.

To reset the inverter to factory settings, access the parameter menu through the digital operator. Locate the reset function in the advanced settings and confirm the reset operation. This will clear all user-defined settings and restore the inverter to its default state.

Regular maintenance includes cleaning the inverter's cooling fans and heat sinks to prevent overheating, checking electrical connections for tightness, and inspecting for any signs of wear or damage. Perform a thorough inspection every six months or as recommended in the user manual.

Ensure that the communication cables are correctly connected and undamaged. Verify the settings for communication protocols such as Modbus or Ethernet, and confirm that both devices are using compatible parameters. Check for software updates that may address known communication issues.

Check the input power supply to ensure it matches the inverter's specifications. Verify that all safety interlocks and emergency stops are disengaged. Inspect parameter settings related to motor start conditions, and ensure that the run command is correctly issued.

The inverter can operate in harsh environments with appropriate precautions. Ensure it is installed in a well-ventilated enclosure with protection against dust, moisture, and corrosive substances. Consider using additional protective coatings if operating in extremely harsh conditions.

To extend the life of the inverter, maintain proper ventilation to prevent overheating, regularly clean and inspect the unit, and operate it within the specified electrical and environmental limits. Ensure that all firmware updates are applied to enhance functionality and reliability.

Inspect the power supply and connections to the display panel. Ensure that there are no loose or damaged cables. If the display is still non-functional, consider resetting the inverter or contacting technical support for further diagnosis.

Integrate the inverter using its available communication ports, such as Modbus or Ethernet. Configure the control parameters to match those of the automation system, and ensure that the programming logic in the PLC or control system accounts for the inverter's operation and feedback signals.