Brother NX-600 Quick Reference Guide

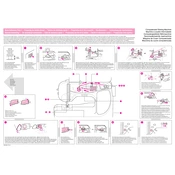

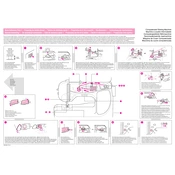

To thread the Brother NX-600, raise the presser foot and turn off the power. Follow the threading path indicated on the machine, ensuring the thread passes through the tension disc and the needle. Finally, pull about 15 cm of thread through the needle's eye.

If your machine is skipping stitches, check that the needle is correctly installed and not bent or dull. Ensure the thread is correctly threaded and that you are using the correct needle size and type for your fabric.

Regular maintenance involves cleaning the bobbin area, removing lint with a small brush, and oiling the hook race every few months. Always unplug the machine before cleaning. Refer to the manual for detailed instructions.

To adjust the tension, use the tension dial located on the front of the machine. Increase tension for tighter stitches and decrease for looser stitches. Test on scrap fabric to find the optimal setting.

A clunking noise may be caused by incorrect threading, a bent needle, or issues with the bobbin. Re-thread the machine, replace the needle if necessary, and check that the bobbin is correctly inserted.

Raise the needle and presser foot, then press the black button on the back of the presser foot holder to release the foot. Align the new foot with the holder and lower the presser foot lever to attach it.

Ensure the feed dogs are raised and clean. Check that the presser foot pressure is adequate for the fabric type. Also, verify that the stitch length is not set too short.

Turn off the machine and raise the needle to its highest position. Loosen the needle clamp screw and remove the old needle. Insert a new needle with the flat side facing the back and tighten the screw.

Check the power connection and ensure that the machine is properly plugged in. If the issue persists, try resetting the machine or consult a professional technician for further assistance.

Ensure that the bobbin is correctly placed on the winder spindle and that the thread is properly guided through the tension disc. Check that the bobbin winder shaft is pushed to the right position.