Brother ND50E Quick Reference Guide

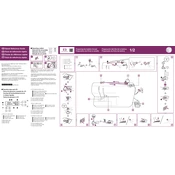

To thread the Brother ND50E, first raise the presser foot and turn the handwheel towards you to raise the needle. Place the spool of thread on the spool pin, pass the thread through the upper thread guide, then down through the tension disc. Pull the thread back up, hook it through the take-up lever, and finally thread the needle from front to back.

Skipped stitches can be caused by a dull or bent needle, incorrect threading, or tension issues. Replace the needle, rethread the machine, and check the tension settings. Ensure you are using the correct needle and thread for your fabric.

Regularly clean the machine by removing lint and dust with a small brush or vacuum attachment. Oil the machine as per the manufacturer's instructions, focusing on the bobbin case and other moving parts. Always unplug the machine before performing any maintenance.

To adjust the tension, use the tension dial located on the front of the machine. For thicker fabrics, increase the tension by turning the dial to a higher number. For lighter fabrics, decrease the tension by setting it to a lower number. Test on a scrap piece of fabric to achieve the desired stitch quality.

Unusual noises may be due to a bent needle, incorrect threading, or lack of lubrication. Check the needle for damage and replace if necessary. Rethread the machine, ensuring proper threading paths. Lubricate the machine as per the manual’s instructions.

Ensure the bobbin is correctly positioned on the winder spindle and the thread is threaded through the bobbin winding guide. Engage the bobbin winder shaft and press the foot pedal gently. If the bobbin does not wind evenly, check for thread tangles or replace the bobbin.

If you experience tension problems, check that the machine is correctly threaded and the bobbin is inserted properly. Adjust the upper thread tension using the tension dial and test on scrap fabric. Ensure the bobbin tension is not too tight or too loose.

For lightweight fabrics such as silk, use a size 9/70 or 11/75 needle. For medium-weight fabrics like cotton, use a size 14/90 needle. For heavy fabrics such as denim, a size 16/100 or 18/110 needle is recommended. Always match the needle size to the fabric being used.

Raise the presser foot lever and turn the handwheel to lift the needle. Press the presser foot release lever located at the back of the presser foot holder. Align the new presser foot with the holder, lower the presser foot lever, and it will snap into place.

Ensure the feed dogs are raised and not set to the dropped position. Check that the presser foot is down and the correct foot is in use for the type of stitch. Adjust the presser foot pressure if needed and ensure the fabric is aligned properly.